Editors note: We have a guest author for this blog post. Robert Dall Senior, my father.

The Accident

On July 28th 2020, I was working on replacing our outdoor stairs when I had a workshop accident which changed my life. I was using my sliding compound mitre saw to cut a backing block. Since the block was small, I made a jig which kept my hand well away from the blade. Something went wrong. There was a bang and my left hand was severed just above the wrist.

My wife Bev, the local paramedics and the doctors of the Vancouver General Hospital saved my life. But now life would take a completely different turn.

Prosthetics

I was fitted with a traditional claw prothesis that fall. Although useful, I was interested in other prosthetics. Something more hand like that could be used for gently holding things. I felt that the claw was hard and could mar surfaces.

During the winter of 2023-2024 I heard about the Victoria Hand. At first, I didn’t realize that the Victoria referred to was Victoria, BC, our provincial capital and some 120 km away as the crow flies.

https://www.victoriahandproject.com

I found that they were using a very unique approach to the manufacture a prosthetic hand. Nick Dechev, Ph.D, P.Eng has designed a 4 finger with opposing thumb mechanical hand which was made of machined metal and cost $5,000. He and his team have used laser scanning and 3D printing to reduce the cost to $300.

Victoria Hand Project Process

- A cast of the stump is made using plaster of Paris casting tape by a prosthetist.

- A positive stump replica is made from the above casting.

- This positive casting is laser scanned into a computer program.

- A 3D printer uses a black plastic filament to print a socket to fit the patient’s stump. The prosthetist fine tunes the fit.

- The hand and wrist are assembled of 3D printed plastic parts with the laser cut stainless steel skeleton. Much of the assembly in Victoria is done by volunteers.

- The hand and wrist are attached to the socket and a figure “8” harness is added.

- The prosthetist then does the final adjustment of harness and mechanism.

- The socket, wrist and hand is painted with tremclad paint. There are six basic colours: Satin Brown, Satin Leather, Satin Black, Satin Island Splash, Satin Peacock Blue, and Patriotic Blue.

After looking at their work around the world and the testimonials, I decided to phone them. I contacted them in March talking to Michael Peirone who gave me lots of information about availability in Canada. VHP provides the hand for free as it is a charitable organization.

I contacted VHP a second time speaking to Abby Koch. I thought that I would try to arrange to get the hand through my trusted prosthetist in Vancouver.

By the beginning of June I had contacted Abby several times and through her Geoff Hall of Custom Prosthetic Services the prosthetist that VHP uses in Victoria.

My wife, Bev, and I decided to extend our planned Vancouver Island trip for a week or so by going down to Victoria and getting the hand through Geoff.

On Wednesday July 17 we met Geoff and Natalie Mainville at his office. Geoff and Natalie made a cast of my stump. Natalie is a BCIT student in Prosthetics doing her final practicum with Geoff. On Friday, Geoff had the 3D printed socket back from VPH. He lined the stump for a tighter fit and we took it to the University of Victoria lab where we meet Abby and toured their facility. There were many computers, laser scanners and 3D printers.

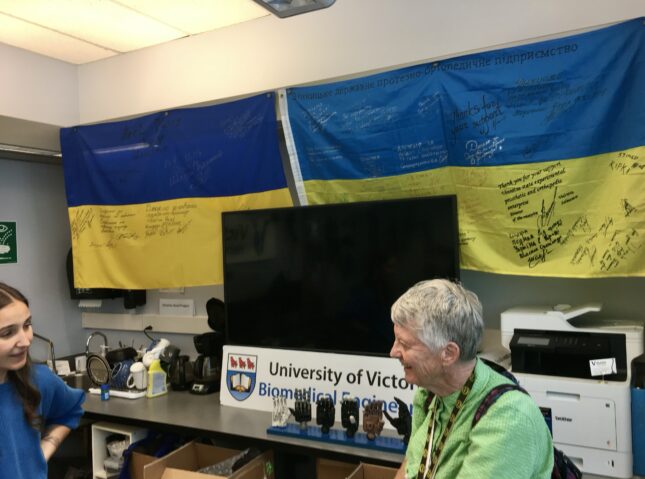

The walls were covered with pictures from all over the world of amputees getting their hands. One wall had the Ukrainian flag on the wall. It was covered with thank you notes and signatures. There was a display of the evolution of the hand from a machined metal prototype that cost $5,000 to the current 3D printed model with a laser cut stainless skeleton for less than $300. We also met the assembly crew which puts that hand together. This task is most often done by around 20 volunteer students.

We watched as a printer quickly churned out the ball joint wrist part for a hand. There is incredible detail in the printed part complete with identifying numbers etc. already in the finished piece.

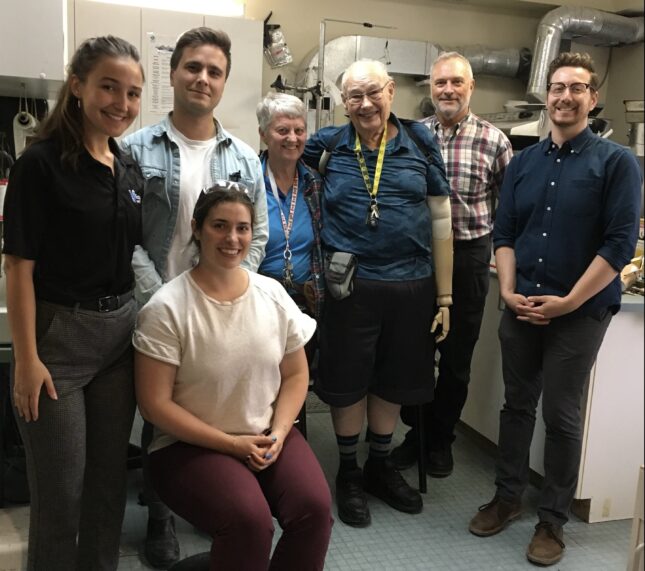

On the following Wednesday, we all met at Geoff’s office. A full crew was there to fit my new prothesis and shoulder harness. As this is leading edge work the process was slow with a lot of interaction between the designers and the prosthetists. Improvements for future hands were noted.

For this process we had two Engineers Abby and Michael, and three prosthetists Geoff, Nolan Fidyk Geoff’s assistant, and Natalie.

Note: Michael is the CEO of VHP and Abby is in charge of North American Development.

For every $300 Canadian Dollars, VHP can provide an amputee with a life enhancing prosthesis. In lieu of payment, I made a charitable donation.

I proudly wear my new hand. Now I have to learn how to use it!